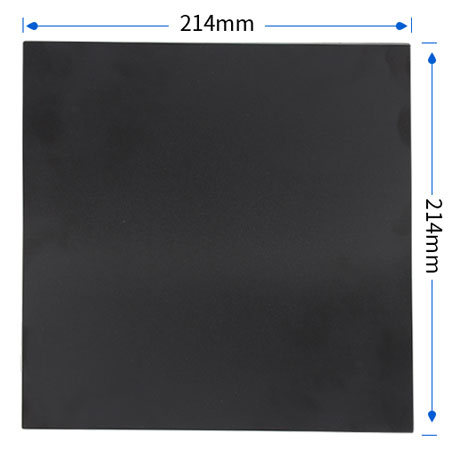

3D Printer Upgrade Parts Build platform Kapton Blue Tape like BuildTak 214 X 214

This is a thin, durable plastic sheet that adheres to the print bed of FFF (fused filament fabrication) 3D printers. It provides an optimal printing surface for 3D objects to adhere to for the duration of a print, while allowing for a clean, easy removal of completed builds. You can put away the blue tape, Kapton, hairspray, ABS juice, Perfboard or other solutions. That is recommended print bed surface for 3D printing

Description

| Item Name | 3D Printer Upgrade Parts Build Mat platform like BuildTak 214mm X 214mm (8.5" X 8.5") |

| Condition | Brand New |

| Brand | OpenBuild |

| Model | OpenBuild |

| Type | Print Bed Build Mat |

| Made For | OpenBuild, Tevo |

| Description | This is a thin, durable plastic sheet that adheres to the print bed of FFF (fused filament fabrication) 3D printers. It provides an optimal printing surface for 3D objects to adhere to for the duration of a print, while allowing for a clean, easy removal of completed builds. You can put away the blue tape, Kapton, hairspray, ABS juice, Perfboard or other solutions. That is recommended print bed surface for 3D printing |

| Key Benefits | Ease of use Creates an optimal bond between the 3D printed object and the build surface for the duration of the print while preventing curling or object coming loose. When builds are complete, the 3D printed object can be cleanly removed with minimal prying or scraping. Longevity Build Mat sheets are more rigid and durable and last longer than traditional methods like Kapton. This reduces time in continually applying print surfaces and extends protection to the original print bed surface. Ease of installation Easy installation to the bare print bed and clean removal without adhesive residue usually with less air bubbles. There is no need for pre-treatments such as hairspray or acetone slurry. Works with MANY filaments Works with ABS, PLA, HIPS, PET+, Brick, Wood & Flexible (TPE) filaments; additionally we have had success with getting nylon and t-glase (PETT) to adhere when used with a thin layer of washable glue stick on the Build Mat surface. This means you can use different filament materials without the need to change the printing surface. Heat Resistant Patent-pending heat resistant composition, developed to withstand the typical temperatures used on heated print beds (i.e. 110-125C). With safety in mind, Build Mat is composed of raw materials that are UL flame rated. |

| How to use | Instructions 1. Wipe down your bare build platform making sure it is clean and free of debris. 2. Trim the BuildMat sheet to match the size of your build plate (if not already). 3. Remove the white adhesive liner and apply the Build Mat sheet to the bare build plate. Start from one edge of the build plate and work your way to the other edge, smoothing the BuildTak sheet with a credit card or decal applicator. 4. Re-level your surface and ensure that the nozzle height is properly set (usually between .10 – .25mm). |

| Support | ABS, PLA, PVA, PET, PETT, HIPS, NYLON, WOOD |

Reviews

There are yet no reviews for this product.